The quality of a filter medium is defined and measured on the basis of the size of particle that can pass through it. The highest class of coarse dust filter compliant with DIN EN 779 is filter class G4 which stops more than 90% of all particles larger than 10μm. Pfannenberg uses G4-class filter media as standard. Effective protection from dust particles is crucial for daily operation: unplanned downtime is very costly and can put people and machines at risk.

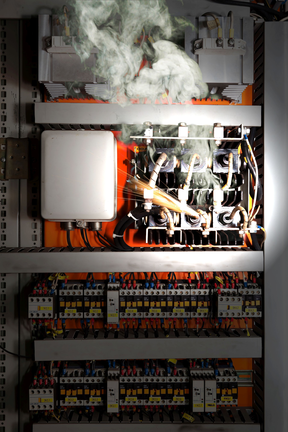

"Overheating is the most frequent cause of the failure of electronic systems as the likelihood that parts will fail rises with the operating temperature", says Dipl. Ing. Jörg Achenbach, Product Manager for Thermal Management of Electrical Enclosures at Pfannenberg. "The correct thermal management of switching systems is crucially important and therefore the choice of filter medium is instrumental in ensuring that particles cannot get into the enclosure and at the same time allowing the right amount of air for cooling to pass through. This interrelationship must always be considered in combination with the fan used. If one of the two components is replaced, the whole system will no longer work as intended – in most cases, the IP protection class is no longer valid and damage can be expected in the long term."

Reliable protection from pollution of all kinds

With their patented, fan-shaped structure, folded filter mats from Pfannenberg offer a much larger surface area which allows large volumes of air to pass through but also increases resistance to damp and jet water. Compared to fleece filter mats, they increase the lifetime of a filterfan by up to 300% as the particles are effectively stopped and the air flow is not impaired. For users this means primarily that much less maintenance is required which saves time and keeps costs low.

The folded filter mats are also characterized their high level of efficiency and economy under the toughest conditions. Categorized in protection class IP55, they are particularly suitable for demanding indoor and outdoor use. The closed framework does not allow unfiltered air to enter into the enclosure. If a special rain cover is attached, the protection class rises to IP56.

Fleece filter mats from Pfannenberg are also categorized in the highest class designated by DIN EN 779 and are the perfect medium for the majority of applications. The filter mats are used primarily in manufacturing operations and guarantee that various types of dust are reliably filtered out of the air while maintaining a high air flow thus effectively protecting the interior of the electrical enclosure from polluting elements.

Irrespective of whether this pollution is wet, dust or dirt, the filter mats offer reliable protection with a high air flow rate. Combined with the patented filterfans from Pfannenberg, operation under the required protection class is guaranteed.

Using filterfans for the thermal management of electrical enclosures is a particularly cost-effective solution. Filterfans create high pressure in the enclosure with cool, filtered outside air which escapes through an opening after it has absorbed the heat in the housing. The click-in mechanism allows the filter mat to be replaced in seconds without the need for any tools.