Outdoor cooling units: Safety of enclosures in harsh environments

Thermal management in enclosures is considered a challenge because every industrial application has its own characteristics.

Particularly in the case of outdoor equipment, system integrators face a highly complex requirement profile: heat, frost, dust and moisture have a powerful impact on the equipment here.

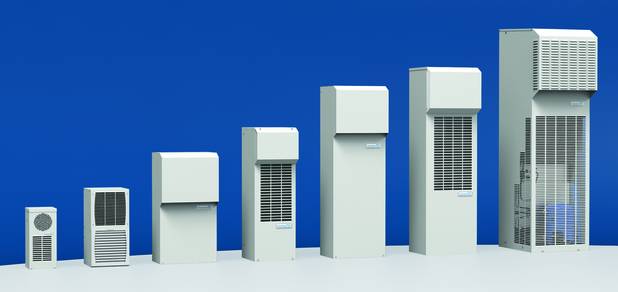

The solution comes from robust outdoor cooling units with high protection classes, and functional design details and characteristics, such as the DTS 3000 series from Pfannenberg.

Weather conditions shut down enclosures

Such applications are increasingly also networked, and now typically have intelligent components installed in outdoor enclosures, many of which are generally sensitive to extremes of temperature.

This results in failures, increased maintenance costs and shorter service lives. Controlling the temperature inside enclosures is therefore a critical task for the planners of outdoor facilities.

Major fluctuations in the weather, salty air near the sea, aggressive vapours in metal industries, and high-pressure cleaners and cleaning chemicals in food production: all of these factors are particularly effective at shutting down standard cooling units, and all do so in very different manners.

And even though some systems can withstand extreme conditions indoors, units for outdoor thermal management require a special design.

From -40°C to +60°C in outdoor operation

One solution is to use robust outdoor cooling units with high protection classes and functional design details that prepare the interior of enclosures even for harsh environmental conditions.

Pfannenberg, specialist in enclosure thermal management, has designed the DTS series 3000 cooling units for 300 to 5,800 kW, specifically developed for force of the elements at outdoor temperatures of -40°C to +60°C, making them suitable for virtually any application.

And because each application comes with its own special requirements, enclosure builders and planning teams can expand the outdoor cooling units from Pfannenberg with heating systems, thermostats and hygrostats to create system solutions with special protective features, e.g. against condensation or corrosion – and all resistant to frost, dust and rain.

Cold and heat: equipment packages allow you to prepare for extremes

With the low ambient (LA) and high temperature (HT) packages available as standard, Pfannenberg creates grading within the series for challenging applications with particularly low or very high outdoor temperatures. The developers at Pfannenberg have thus equipped the LA anti-frost package with reliable protection against condensation.

This protection is ensured by components such as heaters that warm up when required, a safety overflow, an external fan control, and a thermostat that can be mounted inside the enclosure. In this manner, the cold-proof concept also combines heating and cooling in a single unit, which saves e.g. procurement costs and wiring time, and thus also reduces the complexity of the outdoor solution.

When it is predominantly a question of the hard requirements caused by heat, e.g. in the metal industry or during the day in desert regions, temperature-stable compressors and large condensers in the HT package give the components in the enclosure heat-resistant protection.

Dust and moisture: functional construction details

All outdoor cooling units from Pfannenberg fulfil the requirements of the high protection classes IP 56 and N3R, which apply in particular to factors such as dust and moisture. If necessary, designs are also available in NEMA Type 4X, characterised by extremely high corrosion resistance.

For purposes of protection against corrosion damage, Pfannenberg has equipped all outdoor cooling units in the DTS 3000 series with powder-coated cases made from steel or stainless steel up to V4A grade, thus making these too suitable for use under the harshest of conditions.

The components inside the outdoor cooling units from Pfannenberg are likewise treated to ensure corrosion resistance.

Robust: functional construction details

Protection is not just about the material, but also the design details. The air intake is thus positioned near the top of the outdoor cooling unit, so that neither the onset or winter nor a powerful desert wind can block the air inlet with snow or sand. Another example: the coolant circuit is hermetically sealed, not only protecting against leaks, but also making refilling with refrigerant unnecessary. And the excellent sealing of the closed-loop design protects against contamination from outside.

Where the technology needs to work outdoors, every component needs to be packed with power. All of the drive units installed in the DTS 3000 series, such as compressor and fan motors, are fitted with thermal overload protection.

There is a small design lever in order to effectively extend the service life of the compressor, and radial fans with curved, backwards-facing blades in order to generate a high build-up of pressure for the cooling.

With its enclosed motor and a large single ball bearing, they are particularly suited to harsh environments. And with a service life of over 55,000 hours, they last at least twice as long as fans with conventional bearings.

Applications exposed to a lot of dust and sand, possibly also in isolated locations, require a design that is as maintenance-free and filterless as possible.

The fins of the condenser in the outdoor cooling units of the DTS 3000 series therefore have an extra-large spacing of 3 mm, which also makes them less susceptible to dirt deposits in industrial environments with heavy particle pollution, which could block the unit and impair efficiency and operational reliability.

| Description | Language | Type | Size | Download |

|---|---|---|---|---|

Technical Report: Oudoor Cooling Units DTS 3000 |

|

260 KB | Download |