Trusted partner for R&D. Whenever you need us.

Sharing Competence – sums up our mission concerning collaboration with our clients. This is not merely a question of sharing expertise, but of dynamically fostering future innovation. We know what it takes to turn an initial idea into a finished product. And we have the resources to test the capability and potential of new ideas using prototypes. Benefit from our knowledge and technical facilities for your own development project.

You have the idea. We help with the implementation.

With our R&D service, we support in the development and testing of components in the fields of system thermal air conditioning, thermal management and signaling. For this, we can provide a complete range of services of a well-coordinated and experienced engineering team – suited to needs and cost-efficient.

Outside expertise, in-house simplification.

The benefits are apparent. Benefit from the extensive expertise of our specialist team without having to temporarily expand your own R&D services. Without fixed costs rising and without the need to engage in the associated personnel processes, you can continue to concentrate on your core business areas.

Our R&D department offers the full range of services of an engineering practice:

- Conception.

- Development of specifications and test plans (layout).

- Design.

- Flow simulation (CFD).

- Prototype construction.

- Validation of prototypes with regard to relevant requirements.

- Production of design and production documents.

Case study: Product development.

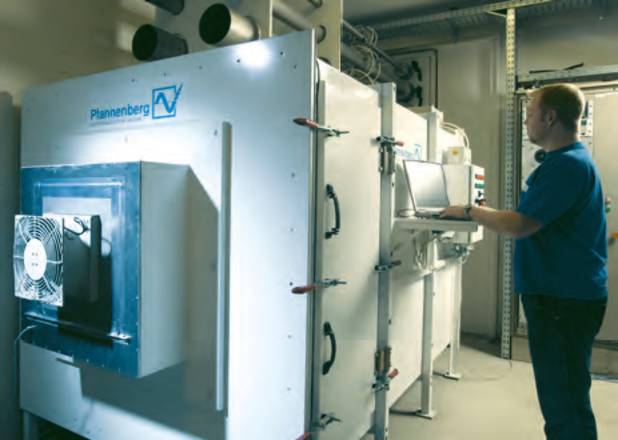

Client: Manufacturer and fitter of multi-function housings in the telecommunications industry. Challenge: The client lacks the resources to provide its customer with an electrical enclosure prototype with an active top-mounted ventilation within 4 weeks.

Solution: Our R&D team develops a precise specification and test plan with the client. After production of the prototype by the due date, it is tested to confirm that it meets the relevant requirements. Both prototype and test report are then sent to the client.

Following successful acceptance by the end customer, the design and manufacturing documents are also passed on. Pfannenberg builds the first 100 units, after which the client takes over the manufacturing.