Case Study

Alarming Marcegaglia‘s plants – world leader in steel processing

Fire alarm devices in a 250,000 m2 manufacturing plant.

Application

Manufacturing – end user.

Marcegaglia is the leading industrial group worldwide in the steel processing sector, with a yearly output of over 5 million tons. The group has operations worldwide with 43 manufacturing plants needing a new fire alarm system. Starting from Gazoldo, the solution will be then implemented in all the other plants.

Challenges

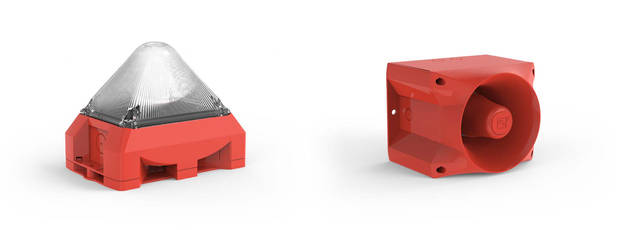

They contacted us after firefighters had blocked the renewal of the fire prevention certificate, believing the system was not up to standard. The engineering firm and the chief of plant security contacted several suppliers that produce acoustic and visual devices for fire alarm. Only Pfannenberg’s PYRA® and PATROL products have passed field tests.

The customer

Marcegaglia is the leading industrial group worldwide in the steel processing sector, with a yearly output of over 5 million tons. The group has operations worldwide with 6,500 employees, 60 sales offices, 210 representations and 43 manufacturing plants covering 6 million square metres. Activities in the steel sector and other businesses generated over 4 billion euro turnover in 2014. Founded in 1959 and fully owned by the Marcegaglia family, the group is headquartered in Gazoldo degli Ippoliti, Mantova (Italy).

La solución: PA 20 + PY X-M-10

La planta de Gazoldo degli Ippoliti aloja las líneas para la producción de rollos de acero, flejes, chapas, perfiles planos, tubos soldados estructurales y de precisión. La planta también alberga las oficinas centrales dedicadas al control de calidad, servicios técnicos, TI y gestión logística de todas las plantas de producción del grupo. Consiste en 38 edificios de unos 80 m x 100 m.

The chosen solution to properly spread the alarm in the each building is a combination of PA 20 sounders (high penetration acoustic devices with 120 dB sound pressure level and 178 m covering distance) with PY X-M-10 beacons (senon flashing light in a compact pyramidal body with the widest EN 54-23 certified coverage) in white and red lens. Sounders give two different alarm signals – one for pre-alarm and one for alarm – each one supported by a white or red flashing light. The combination of the products in the installation differs depending on the background noise and visibility in the specific building.

Future plans

Next stage in collaboration with the Marcegaglia’s chief of plant security and the system integrator’s CEO will be the extension of the same solution in other manufacturing sites – starting from Ravenna, where Marcegaglia has set up its by far biggest plant (spreading over a 540,000 m2 surface, 225,000 covered) working as the nerve-center for integrated logistics as well.

| Description | Language | Type | Size | Download |

|---|---|---|---|---|

Case Study Marcegaglia |

|

2.0 MB | Download |