Case Study

Sirocco - Reliable alerting in the Gleinalm Tunnel

Fire protection is given the highest priority in tunnel construction. Should a fire break out and produce smoke, the fire alerting system must function reliably so that countermeasures can be put in place as quickly as possible to protect human lives. As part of a comprehensive modernization and reconstruction project, Sirocco Luft- und Umwelttechnik GmbH has been commissioned by ASFINAG, the operator of the Gleinalm Tunnel in Austria, to install ventilation dampers to ventilate the tunnel and extract smoke gases. Each damper is fitted with a sounder/flashing light combination from Pfannenberg which will provide an alert in the event of fire.

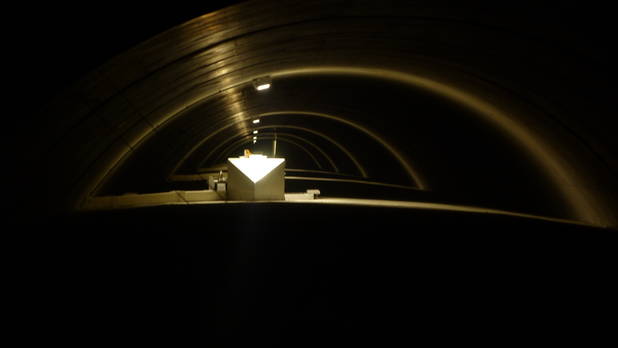

The Gleinalm Tunnel is a very busy tunnel on the A9 Pyrhn highway in Austria. It is 8,320 meters long and connects Leoben with the outskirts of Graz in Styria and is used by approximately 21,000 vehicles every day. It currently consists of one tunnel for traffic with an exhaust duct immediately above it which is also used to extract smoke in a controlled fashion should there be a fire. There is a ventilation damper fitted every 100 meters along the whole length of the tunnel. A new tunnel is currently being built and is expected to be opened for traffic in summer 2017 after which the existing tunnel will be renovated with completion of the whole project planned for 2019. According to ASFINAG, total investment in the new construction work and the renovation of the existing tunnel is approximately €260 million. As part of the project, Sirocco is replacing the ventilation dampers in the duct for the existing tunnel as well as installing new dampers in the duct for the new tunnel.

80 sounder/flashing light combination devices per exhaust duct

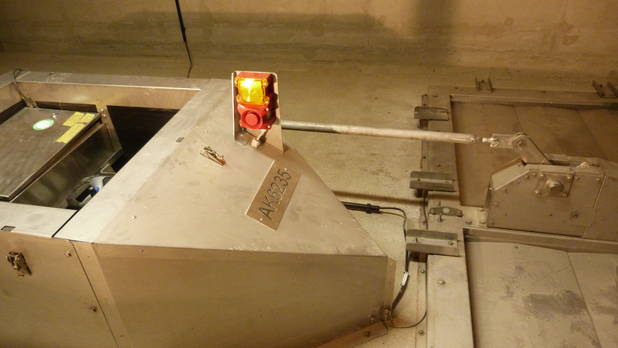

Each of the two exhaust ducts has around 80 ventilation dampers which are distributed along the length of the tunnel. They are all fitted with a PA X 1-05 sounder/flashing light combination from Pfannenberg’s PATROL range. Each signaling device can produce sound at 100 dB(A) and a light intensity of 5 J when flashing. Normally, the exhaust duct would be empty of people and air extraction would start automatically. However, when maintenance work becomes necessary, the staff responsible need to enter the duct. Should the fire alarm be triggered, they all need to exit the duct as quickly as possible. The visual and audible alert is conveyed via the signaling devices. Smoke extraction cannot start until confirmation has been received that the evacuation is complete.

Full compliance with all the tender specifications

Pfannenberg was able to meet all the specifications in the tender issued by ASFINAG with its PA X 1-05 sounder/ flashing light combination device. The tunnel operator had asked for visual and audible signaling devices compliant with protection class IP66 with yellow covers and a nominal voltage of 24 V DC in an aerodynamic design that would occupy little space in the ventilation duct but nevertheless be widely seen and heard. ASFINAG had a special requirement concerning the flashing light: this was to offer a frequency of 3 Hz and light intensity of 3 J. Both criteria were easily fulfilled by the PA X signaling devices as was the requirement for a two-tone sound issued at intervals of at least 0.3 seconds. The PA X 1-05 guarantees norm-compliant fire alerting and also allows projects to be planned with certainty.

Precise calculation of the required sound volume

Pfannenberg 3D-Coverage is a new practical and systematic way to plan the effective performance of audible and visual signaling devices in a given space. Even in the initial stages of a project of this kind it can make a reliable statement about the size of the area actually covered by the signaling devices. By taking the environmental situation into account, the experts at Pfannenberg can use 3D-Coverage to determine how loud the signal needs to be. This prevents incorrect dimensioning and also ensures that compliance with all the industrial norms and regulations is achieved in a cost-effective and energy-efficient manner.

Thanks to their well-thought-out design, we can simply pre-assemble the PA X sounder/flashing light devices which will allow us to configure them under optimum conditions in the workshop. […] Where performance is concerned, the sounder/flashing light combinations from Pfannenberg meet all the requirements imposed by ASFINAG. We are completely satisfied.

Simple installation

In selecting a sounder/flashing light combination, the industrial ventilation specialists at Sirocco were looking for simple, fast and safe installation as well as fulfillment of the tender criteria. PA X sounders and lights are pre-wired at the factory making them quicker to fit and install. An incorrect installation is practically impossible. “Thanks to their well-thought-out design, we can simply pre-assemble the PA X sounder/flashing light devices which will allow us to configure them under optimum conditions in the workshop,” explains Reinhard Kripsch, the project leader at Sirocco. “Then they just need to be secured with screws in the ventilation duct. There will be no need to open up the devices at the building site, saving time and cutting the amount of work. Where performance is concerned, the sounder/flashing light combinations from Pfannenberg meet all the requirements imposed by ASFINAG. We are completely satisfied.”

Summary

The flashing frequency of 3 Hz requested by the tunnel operator ASFINAG was modified to 1 Hz as the project developed. This did not present a problem for the PA X 1-05. From 2017, a total of 160 sounder/flashing light combinations from Pfannenberg will therefore provide safe fire alerting in the air extraction ducts of the newly built tunnel and its modernized counterpart in the Gleinalm Tunnel in Austria.

Facts at a glance

Task

- Visual and acoustic fire alarm in a tunnel

- Fulfillment of all conditions of the ASFINAG tender with regard to hood color, nominal voltage, flash frequency, tone

- Easy and fast mounting of the signaling devices

Challenges

- Dimensioning of signaling devices using the Pfannenberg planning method 3D-Coverage

- Fulfillment of all tendering requirements of ASFINAG

Technique applied

- 160 Flashing Sounders PA X 1-05

Success factors

- Reliable, prior planning with 3D coverage together with the customer

- Pfannenberg is the only supplier of signaling devices that meet all of the requirements

- Uncomplicated installation and maintenance of the signaling devices due to the pre-wiring

| Описание | язык | Тип | Размер | Загрузить |

|---|---|---|---|---|

Case Study Sirocco |

|

200 KB | Загрузить |