Introducing the NEMA cooling units (DTS 3xxx).

- outdoor applications

- ambient temperature up to +55 °C

- harsh environment

- food & beverage

- UL listed

What is NEMA?

National Electrical Manufacturers Association (NEMA) is the association of U.S. manufacturers of electrical equipment that defines the main set of construction standard for the United States and Canada.

Adherence to these standards is guaranteed by the UL certification.

NEMA coding (Type 12, 3R/4, 4/4X) can be compared with the IP coding (IP 54, 56, 56) but compared to the latter is more comprehensive and includes other factors such as protection against corrosion.

Pfannenberg cooling units from NEMA series are UL listed.

| NEMA PROTECTION | 12 | 3R/4 | 4/4X |

|---|---|---|---|

| Contact with internal content | x | x | x |

| Falling dirt | x | x | x |

| Dripping or splashing water | x | x | x |

| Dust | x | x | |

| Oils and coolants | |||

| Sleet and ice | x | ||

| Water jets | x | ||

| Corrosion | x | ||

| IP EQUIVALENT | IP 54 | IP 56 | IP 56 |

When do you need a NEMA cooling unit?

Some examples:

- Along roads and highways

- In desert environments

- Food & beverage applications (stainless steel 304 # 3 brushed)

- Water management and recycling applications (washdown stainless steel)

- In textiles, paper industry or glass and ceramics processes

Outdoor NEMA Type 3R/4.

| Type | Cooling capacity | Rated voltage | Dimensions (HxWxD) |

|---|---|---|---|

| DTS 3031 | 300 W | 115 / 230 V | 394 x 178 x 229 mm |

| DTS 3061 | 680 W | 115 / 230 V | 515 x 254 x 279 mm |

| DTS 3161 | 1100 W | 115 / 230 V ; 1~ | 748 x 395 x 294 mm |

| DTS 3161 SL | 1300 W | 115 / 230 V ; 400 / 460 3~ | 914 x 307 x 307 mm |

| DTS 3165 | 1600 W | 115 / 230 V ; 400 / 460 3~ | 914 x 305 x 302 mm |

| DTS 3261 | 2000 W | 115 / 230 V ; 400 / 460 3~ | 1209 x 395 x 326 mm |

| DTS 3265 | 2900 W | 115 / 230 V ; 400 / 460 3~ | 1347 x 406 x 301 mm |

| DTS 3461 | 4000 W | 400 / 460 3~ | 1502 x 403 x 468 mm |

| DTS 3661 | 5500 W | 230 V ; 400 / 460 3~ | 1665 x 485 x 620 mm |

Washdown stainless steel NEMA Type 4/4X.

| Type | Cooling capacity | Rated voltage | Dimensions (HxWxD) |

|---|---|---|---|

| DTS 3031 SS | 300 W | 115 / 230 V | 394 x 178 x 229 mm |

| DTS 3081 | 680 W | 115 / 230 V | 515 x 254 x 279 mm |

| DTS 3181 | 1100 W | 115 / 230 V ; 1~ | 748 x 395 x 294 mm |

| DTS 3181 SL | 1300 W | 115 / 230 V ; 400 / 460 3~ | 914 x 307 x 307 mm |

| DTS 3185 | 1600 W | 115 / 230 V ; 400 / 460 3~ | 914 x 305 x 302 mm |

| DTS 3281 | 2000 W | 115 / 230 V ; 400 / 460 3~ | 1209 x 395 x 326 mm |

| DTS 3285 | 2900 W | 115 / 230 V ; 400 / 460 3~ | 1347 x 406 x 301 mm |

| DTS 3481 | 4000 W | 400 / 460 3~ | 1502 x 403 x 468 mm |

| DTS 3681 | 5500 W | 230 V ; 400 / 460 3~ | 1665 x 485 x 620 mm |

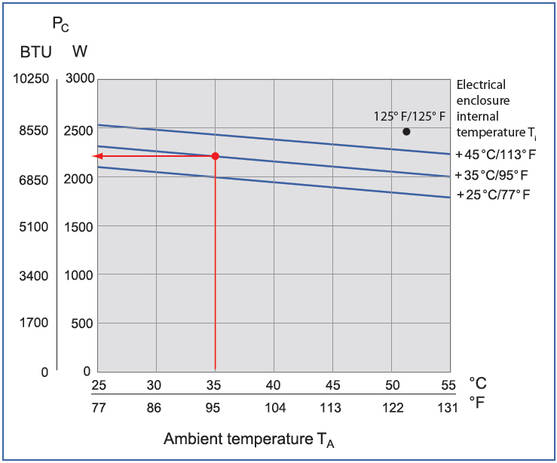

Cooling based on ACTUAL performance.

Pfannenberg offers complete cooling capacity charts based on actual performance, which provides for more reliable data and proper sizing.For years, competition units have been rated at maximum operating points (i. e. 51 °C). These units must ALWAYS run at maximum capacity to achieve maximum efficiency, often at a temperature too hot to properly cool electronics. Running below maximum conditions results in a 20–30 % reduction in cooling efficiency.

The FACTS about Pfannenberg DTS 3000 cooling units ...

High ambient performance.

The DTS 3000 series was designed utilizing high temperature compressors and larger condensers to best perform in outdoor applications which require a maximum ambient temperature of 55 °C – such as roadside, rooftop or desert locations. The indoor NEMA Type 12 units can also handle maximum rating and can be mounted near high temperature equipment such as industrial ovens, furnaces and boilers. High ambient options are also available to 60 °C.

Environmentally friendly.

For the past 5 years, Pfannenberg has used compressors for HFC-free R134a refrigerant, not R22 refrigerant – which is not considered environmentally safe. Due to upcoming tougher environmental standards on industry, this refrigerant cannot be used after 2010 on new machines.

Upgrading existing R22 designs will be costly and difficult because R134a compressors are typically larger in size.

Active condensate water management.

Passive condensate management relies on the refrigeration discharge line that has high temperature gas flowing through the pipe to evaporate the moisture collected in the condensate tray. When the refrigeration cycle is off, the moisture is not being removed. Active condensate management utilizes a PTC (positive temperature co-efficient) heating element. These elements need very little mounting space and feature a high power density.

After the water has been removed from the condensate tray, the element reduces its power consumption automatically. The control of heating element is independent from the refrigeration control.

Specially designed backward curve impeller fan.

A backward curved impeller fan uses one large bearing, unlike a typical blower which has two smaller bearings. The larger bearing and sealed motor provide a fan service life of over 55,000+ hours in harsh industrial environments versus a typical blower life expectancy of only 20–30,000 hours. The backward curve design creates a natural right angle for a long internal air path instead of forcing the air path from a blower or allowing a short air path that can create short cycling on the inner circuit.

Coated condenser pipes provide cost-effective solution.

Most condenser coils are coated because they’re located in a harsh natural (saltwater) or manufacturing (chemicals) environment. Corroded uncoated condenser coils lead to a rapid loss in capacity, reduced efficiency, and increased energy consumption. Unit longevity can be a serious problem in harsh environments: uncoated coils in harsh situations have been known to fail in less than a year. A coil properly coated with a quality corrosion protection system can withstand harsh environments, providing long-term and cost-effective service.

Wide condenser fin spacing for higher performance.

Wider condenser fin spacing optimises the balance between higher performance and clogfree operation. Wider fin spacing allows for larger particles to pass through the condenser while maintaining overall capacity. Narrow fin spacing typically requires a filter to keep the condenser free of debris thus reducing the airflow and the overall capacity. Many applicationscan go filter-less creating a more maintenance-free solution.

Hermetically sealed for longer service intervals.

Pfannenberg uses hermetically sealed compressors. Units that use gasketed valves for "easy" re-charging need to be recharged because of the presence of the valve itself. If they are not re-charged every 2–3 years, the unit will not run at 100 % capacity.

In large industrial plants, it is very common for approximately 60 % of the cooling units to be running at reduced capacity due to the loss of refrigerant with most maintenance personnel being unaware of the danger to their electronics.

Designs for food and beverage applications.

Pfannenberg’s DTS 3000 series NEMA Type 4/4X models have covers made from 304, #3 polish stainless steel with a vertical grain for industrial and food grade applications. Non-polish finishes can attract dust and other non-desirable contaminants. The lower carbon 'variants' (316L) are also available for most designs and are considered more corrosive resistant vs. 304 stainless steel.

Rugged metal covers provide added protection.

In industrial applications, decorative plastic grills do not always withstand the rigors of the environment and show more wear and tear than metal covers. Metal covers not only create a more rugged unit, but can also be painted easier to match the design of the overall machine.

| Description | Language | Type | Size | Download |

|---|---|---|---|---|

UL certificate |

|

66 KB | Download |