A wind farm or wind park - also called a wind power station or wind power plant - is a group of wind turbines in the same location used to produce electricity. Wind farms vary in size from a small number of turbines to several hundred wind turbines covering an extensive area. Wind farms can be either onshore or offshore.

Because they require no fuel, wind farms have less impact on the environment than many other forms of power generation and are often referred to as a good source of green energy.

The world‘s leading system manufacturers and their suppliers place their confidence in our innovative thermal management and signaling solutions.

Humidity and condensation control

Plants in offshore wind parks are exposed to high humidity – reliable thermal management is provided by air/air heat exchangers which hermetically protect the interiors of electrical enclosures from harsh environmental conditions. Thermostats and hygrostats ensure a consistent temperature which is relevant for the protection against the formation of condensation inside the cabinet. They control humidity and temperature, and can also be combined with heaters or filterfans for electrical enclosures.

Controls protection against dust and sand

Where the air is contaminated with dust and sand, 4th generation filterfans provide reliable cooling for the control units. A patented fluted filter mat, flow-optimised fins and rotor blades allow for maximum airflow and minimum energy consumption. In almost all modern systems frequency converters are used. Air/water heat exchangers are the appropriate means of maintaining the maximum availability of their sophisticated control electronics even at high ambient temperatures. The maintenance-free units made from corrosion-free stainless steel provide energy-efficient cooling, even when exposed to major dust and dirt contamination.

Rotor safe start up

To start up the rotor safely after a stoppage due to weather or maintenance, we have developed a compact, vibration-resistance certified fan heater. With performance levels ranging from 250 to 1,000 W, with a storage and operating temperature of –40 °C to +70 °C it delivers pitch regulation availability even under extreme conditions.

Generator and gearbox cooling

A Green Series cooling unit is used to cool the electrical generator inside the nacelle.

Some turbines have water-cooled generators, therefore they use chillers from the EB 2.0 WT family for this purpose.

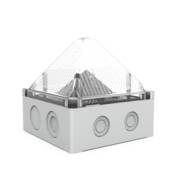

Signaling and alarms

Our extremely robust signaling solutions contribute to the smooth operation of wind energy plants – including obstacle warning

lighting for aviation, state displays for the tower lifts and audible signals when starting up the plant and fire alarms.

Statistics and trends

Aug 2022. The global wind industry had its second-best year in 2021, with almost 94 GW of capacity added globally, trailing behind 2020’s record growth by only 1.8%. 21.1 GW of offshore wind capacity was commissioned in 2021 - 80% of which in China alone. Total global wind power capacity is now up to 837 GW, helping the world avoid over 1.2 billion tonnes of CO2 annually – equivalent to the annual carbon emissions of South America.

557 GW of new capacity is expected to be added between 2026 under current policies. That is more than 110 GW of new installations each year until 2026.

However, this growth needs to quadruple by the end of the decade if the world is to stay on course for a 1.5C pathway and net zero by 2050.

(source GWEC Global Wind Report 2022)